-

-

(+91) 987 909 1953

(+91) 846 040 4010

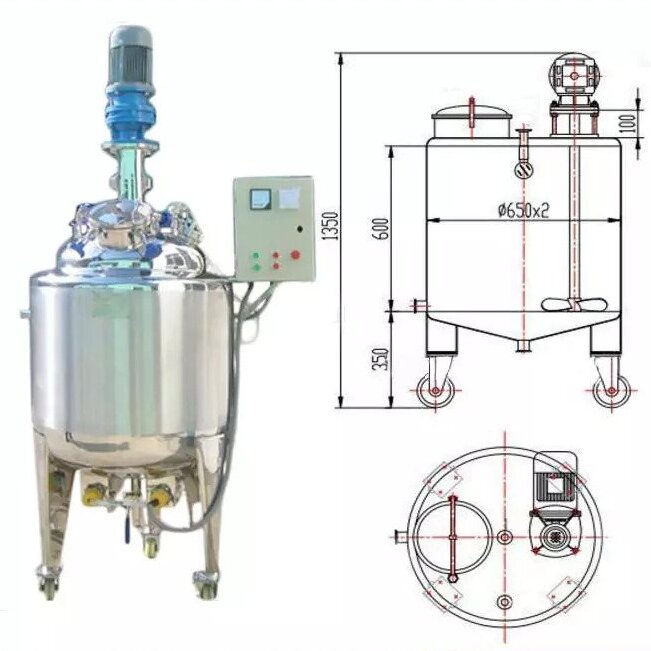

Liquid Mixing Agitator

Chemical Liquid Mixer Agitator

Liquid Mixing Agitator

Besides sophisticated state of the art manufacturing facility "Abster" provides wide ranging research, design, development and consultancy services in the area of fluid agitation and mixing technology. Design and consultancy services are also available on a proprietary or special contract basis.

Special requirements in blending, dissolving, heat transfer temperature uniformity, gas dispersion, impeller configuration for high viscosity, prevention of stratification, flow pattern effectiveness, emulsification to suit wide variety of tank geometry are expertly assessed and met with Mixrite Agitators.

Through advances in Agitator blade geometry and optimum speed selection, we at Abster, strive towards getting maximum flow at minimum power consumption.

Mixing Agitators are of particular value to those process plants where increased efficiency, reliability and innovation are high on the list of company objectives.

| Portable Agitator Selection Chart | |||

| Tank Volume [ m3 ] | 0.3 - 0.5 | 0.5 – 1.0 | 1.2 – 4.0 |

| Recommended Tank Height [met] | 1.0 | 1.1 | 1.4 |

| MMS Model | MM-5 /FMM-5 | MH-5 / FMH-5 | MM-10 / FMM-10 |

| HP | 0.5 | 1.0 | 1.0 |

| RPM | 960 | 1500 | 960 |

*Specification can be changed as per customers requirements

Liquid agitator mixer

Our factory Abster high speed agitators are available in 316 SS material of construction Agitators are ideally suited for tanks of relatively small volume capacity. These compact Agitators are available with either mounting bracket and C clamp arrangement or Pedestal mounting arrangement. The delivery period for these Agitators is shortest in view of the standard design and inventory maintained by the company.re specialized in producing stainless steel tanks,liquid agitator mixer , Including storage tank, Mixing Tank, Fermentation Tank, Reactor Tank. All these tank could be made according to customer's requirement Industrial chemical vertical fertilizer liquid soap paint tank agitator mixer Material including: 304SS, 316LSS or other grade according to customer's requirement.

Surface finish options of the stainless steel tank including: Mirror Finish, Satin finish, 2B finish, Or EP. Mixing tank have various mixer option: Paddle, Anchor, high shear etc choice.