-

-

(+91) 987 909 1953

(+91) 846 040 4010

Agitator

Agitator

What is the purpose of an agitator?

An Agitator is used for mixing different process media – liquids, gases and solids in chemical addition or Pharmaceutical Ingredients. The agitator imparts energy through mechanical mean by rotating a shaft on which there is an impeller designed specifically for the duty. This could be axial pumping, gas induction, flocculating, high viscosity products, high & low shear mixing etc. An agitator is also used in the Water Industry for adding various chemicals to bring the source water up to drinking water standards

What are the various parts or components of an agitator?

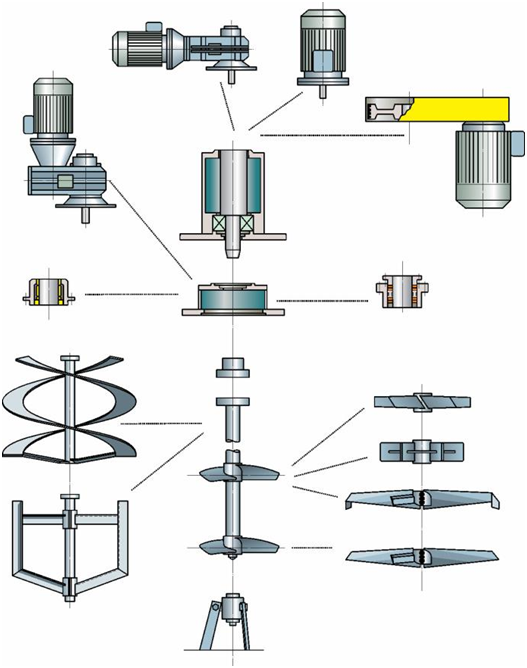

An Agitator is generally made up of a three main components – a shaft with impellers, a mechanical seal and motor with option of gearbox for lower RPM duties.

The agitator is mounted onto the vessel or via a supporting bridge in the water industry. The mechanical seal has a number of options depending on the duty – single/double mechanical seal, dry or wet mechanical seal, gas lift off mechanical seal that is related to the duty involved.

An agitator shaft is connected to the drive unit (motor & gearbox) and where the impellers used for the mixing are welded or bolted onto. There are options for magnetic driven units where there is a hermetic seal as opposed to mechanical.

What are the different types of agitators and their selection criteria?

Agitators can be simplified into Bottom Entry Agitator, Side Entry Agitator and Top entry Agitator depending on the duty & scale of the application to be mixed.

90% of Agitators are a Top Entry Agitator in API / Chemical / Water industries. The main advantages of a Top Entry Agitator is that it can handle a larger variance in viscosities and specific gravities and also the fact that the mechanical seal is not in the liquid.

The remaining 10% include Bottom Entry Agitator, Side Entry Agitator and Bottom Entry Mag Drive Agitator. Milk silos & very large holding tanks use side entry agitators not necessarily for mixing but to keep the process media moving and keep the milk cool while bottom entry agitators are more common in the Biotechnology sector, where it is a magnetic driven unit (see below).

The applications for a Magnetic Drive Agitator generally fall under the following main headers (but is not limited to):

- Blending

- Heat transfer

- Homogenisation

- Reactor

- Suspension

- Storage

- Continuous reaction

- Fermentation

- Hydrogenation

Depending on the industrial sector the customer is in, the mechanical & material suitability for each application can differ greatly. Each of the applications have a typical impeller type that is suited to deliver the turbulence necessary to mix the ingredients.

What are tank mixers? How do you size a tank mixer?

Tank mixers are the same as tank agitators which is an agitator mounted on a tank to aid process operations with fluid mixing.

Tank mixers are sized by taking into account the conditions of the application & industry. This impacts material selection, electrical & mechanical loading and performance criteria. The customer will generally have a starting point and we work with them to build a picture of the overall requirement.

Required sizing details are:

- Tank Dimensions

- Duty Requirement

- Design & Operation Temperatures & Pressures

- Electrical duties

- Mechanical seal duties

- Mixing requirements such as Liquid-Liquid Mixing, Liquid-Solid Mixing etc

- Materials of construction

What is a slurry agitator?

A slurry is any liquid with some solids contained in the solution. A slurry agitator can handle such liquids and provides the mixing required.

A slurry agitator is often used to keep the solids in suspension to prevent settling out and forming on the base of the vessel or bulk tank before being transferred to the next stage of processing.

Examples would be in the API sector where solvents contain the active ingredient and are then filtered via a filter dryer.

What are the various agitator impeller types?

Standard Hydrofoils: these impellers are axial flow high efficiency general purpose – they are designed to offer mixing with low Power requirements. They are also low shear and will not damage sensitive process media.

Wide Blade Hydrofoils: these impellers are axial flow high efficiency – general purpose – they are designed with higher pumping in mind in comparison to the Standard Hydrofoils impellers. They are low shear and they use more power however they would still use less power in comparison to the Pitched or Straight Blade Turbines.

Pitched Blade Turbines: are high pumping axial flow impellers, they are high shear so that could damage sensitive Process Media.

Straight Blade Turbines: are radial flow impellers, they are also high shear and are used for suspending solids where uniform suspension is required or for moving heavy liquids off the bottom of Tanks. Some applications of this are in the biotechnology sector.

RCI (Retreat Curve Impellers): can be used on Glass Lined Tank/Agitators, they offer lower shear than the Straight Blade Turbines with lower power requirements. They are usually used as a Bottom Impeller because they can be positioned very close to the curve of the bottom dish of the Tank, the blades curve upwards and they are also curved towards the end of the blades.

Gas Dispersion Impellers: are used for Mixing Gas into Liquids.

Rushton Turbine: is a gas dispersion impeller for mixing Gas into Liquids, such as hydrogenation and chlorination applications

Saw Tooth Disk or Dispersion Blade Impeller: is used for High Shear applications as they create lots of turbulence for breaking down solids. Typically used in the food sector, paints and other abrasive applications.

What is the difference between an agitator and a reactor?

The Agitator is a component for Mixing the contents of Reactor Vessels, typically found in API or Chemical sectors.

Which type of agitator is used for viscous liquids?

As the viscosity of the liquid media increases, the effectiveness of axial impellers decrease. For these applications, you use a number of impeller types better suited. These include UZ, Anchor, Helical coil and Transitional flow impellers

Batch mixing versus Continuous mixing?

- Batch mixing – if you need residence time for reaction, crystallisation, or storage capacity for downstream processing.

- Continuous mixing – if you have fast reactions or a fully continuous manufacturing process.

- Semi batch – using batch stirred tank vessels in combination with recirculation loops with static mixers or rotor stator mixers.

How can Abster helps you?

We are doing business since 2000, so we have in vast mixing expertise and industry knowledge.

If you have a particular application or requirment about agitation a or mixing in mind for an agitator / tank mixers why not complete one of our forms below and submit it to our product specialist team at sales@abfindia.co.in