-

-

(+91) 987 909 1953

(+91) 846 040 4010

Stearic Acid Drum Flaker

Cooling Rotary Drum Flaker for Softener/Wax/Stearic Acid Production

Product Description

Drum Flaker is used for transforming molten material into solid flakes. The heat of the melt is absorbed by means of Cooling or Chilled Water in the solidification process (based on the melting point).

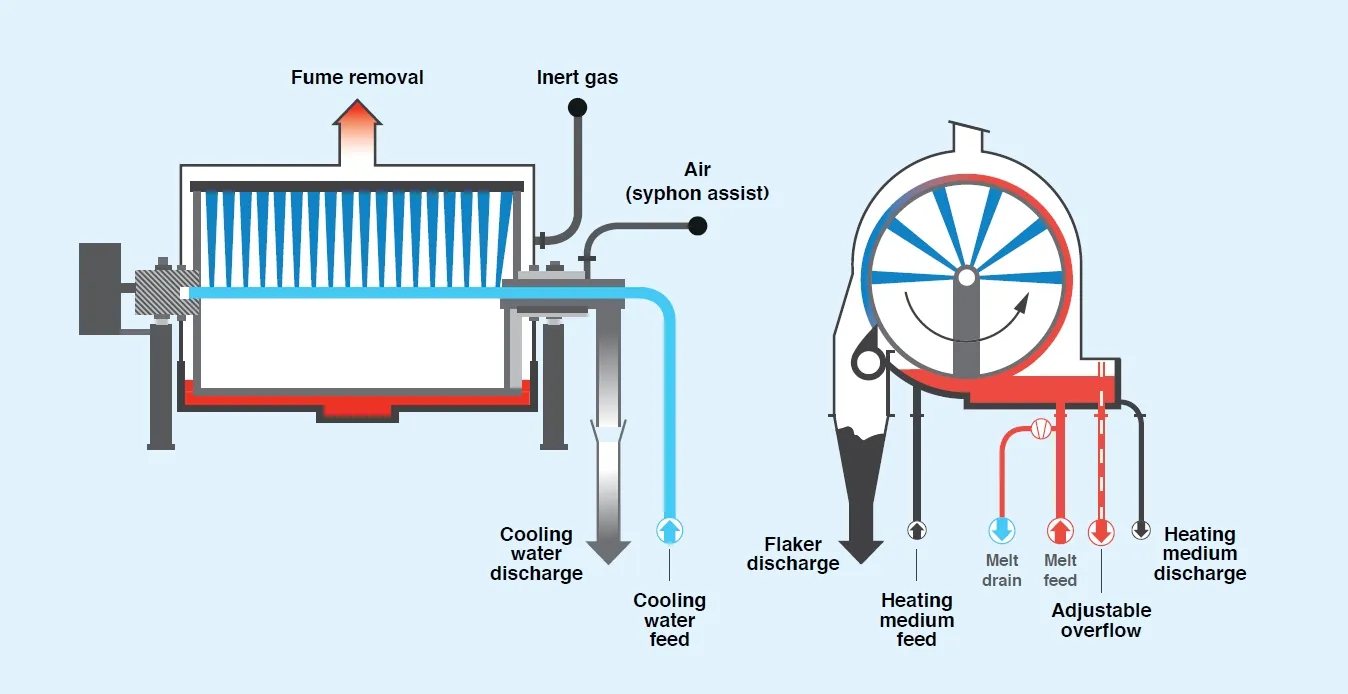

A Flaker generally consists of the following: Cooling Drum, Feeder, Cutter, Drive, Chassis, Cover, Isolation System, Heater, Auxiliary Mechanisms, and Electric and Control Panels. The following figure illustrates a drum flaker:

High quality condensation rotary drum flaker can make the heated fluid which is in trough to stuck on the revolving cooling roller through the rotation of the cooling roller firstly, then cut it into flakes through adjustable scraper.

Thus it completes the conversion from liquid to solid flakes.

It is widely used in chemical and pharmaceutical and other industries.

The drum flaker improves the quality of the final flakes product compared with the product made by crusher.

Furthermore, this machine is easily to operate with good quality.

The thickness and output of this flaker depends on the raw material characteristics, drum speed and feeding speed.

The flake specifications can be customized.

Applications

1. For continuous drying of viscous, pasty and sticky materials in food, chemical and pharmaceutical industry.

2. Heating area: 1.12-10.6 M2

3. Evaporation capacity: 40-60 kg water / hour

4. Working type: continuous

5. Heat source: steam

Technical Advantages

1) High heat efficiency: Heat loss is mainly caused thermal radiation. Heat efficiency can be as high as 90%.

2) Short drying time: The drying process only takes 10-15 seconds. So drum dryer can be used for drying heat sensitive material.

3) Uniform drying: Heat transfer direction and coefficient all over the drum surface are the same. And wet material can be evenly spread over the drum surface. Wet material can be uniformly dried.

4) Long life span: Rotary drum is electro-polished and well heat treated to increase the smoothness and hardness.

5) Flexible application: Drum surface temperature, rotating speed, wet material film thickness are all adjustable to satisfy materials with different moisture and drying time.

6) Compact size: The drying chamber is very compact in size. Only need small installation space.

7) Low operation cost: The whole machine is very simple and reliable. It can be used for many years with little repair and maintenance.

8) Highest hygienic standard: Indirect heating and electro-polished drum surface can assure highest hygienic working conditions.

Drum Flaker working Principle

It consists of a rotating drum with a cooling liquid sprayed on the inside and a product specific application method for applying the molten product to the drum surface. Standard applications methods are; a dip feed pan usually used for low viscosity products,applicator roll usually used for heat sensitive products or agitator roll usually used for super-cooling products. The solidified product is 100% removed from the drum surface by ridged knife-bar assembly.

Drum Flakers are the most compact and efficient method to cool an incoming molten product to a solid flaked product utilizing thin film continuous cooling via conductive heat transfer. Cooling Drum Flakers are utilized in food, chemical, environmental, and pharmaceutical applications for products such as acetic acid, calcium chloride, caustic soda, edible oils, fatty acids, polyethylene glycol, steric acid, waxes and zinc stearate.

Main Technical Parameters

Model |

Drum Specifications (mm) |

Motor Power (KW) |

Hot shaft Speed (r/min) |

Reference size (mm) |

||

L |

W | H | ||||

DZ-1 | 600X600 | 2.2-3 | 0.3-15 | 2400 | 1480 | 1410 |

DZ-2 | 800X1200 | 3-5.5 | 0.3-15 | 3360 | 2000 | 1600 |

DZ-4.5 | 1200X1200 | 5.5-7.5 | 0.3-15 | 3730 | 2250 | 2050 |

DZ-7.5 | 1400X1800 | 5.5-11 | 0.3-15 | 4460 | 2460 | 2350 |

DZ-9 | 1600X1800 | 7.5-15 | 0.3-15 | 4460 | 2600 | 2550 |

DZ-22 |

2300X3000 |

11-18.5 |

0.3-15 |

7200 |

3900 |

2350 |